Innovation and Precision

Total-Gép Kft

Our company is a 100% Hungarian-owned enterprise operating in the manufacturing sector since 2010. Our activities are divided into two main areas: Solar technology and machinery manufacturing.

The increasing demand for renewable energy sources encourages more stakeholders to implement solar installation projects. Our company, Total-Gép Kft., specializes in manufacturing solar panel mounting structures, and we take pride in offering innovative solutions to our clients. Our products are known for their reliability, long service life, and ease of installation.

Material Use and Design

Our mounting structures are made from high-quality materials that meet the strictest international standards (ISO 9001 and EN 1090). The most commonly used materials in our production process include:

• Steel (S355 grade): Hot-dip galvanized with corrosion protection, maintaining stability for 25–30 years.

• Stainless Steel (A2, A4): Specifically used in highly corrosive environments, such as coastal installations.

During the design process, we focus heavily on aerodynamics, optimal tilt angles (20°–40°), and resistance to wind forces. Our structures can withstand wind speeds of up to 160 km/h and snow loads of 1.5 kN/m².

Manufacturing Process

1. Design and Optimization:

The process begins with project parameters provided by the client. Our engineers use CAD-based modeling tools (e.g., SolidWorks) to create designs tailored to the specific requirements of the installation site.

2. Prototyping:

Based on the initial designs, we produce prototypes that undergo rigorous testing in our laboratory. These tests evaluate load-bearing capacity, weather resistance, and installation efficiency.

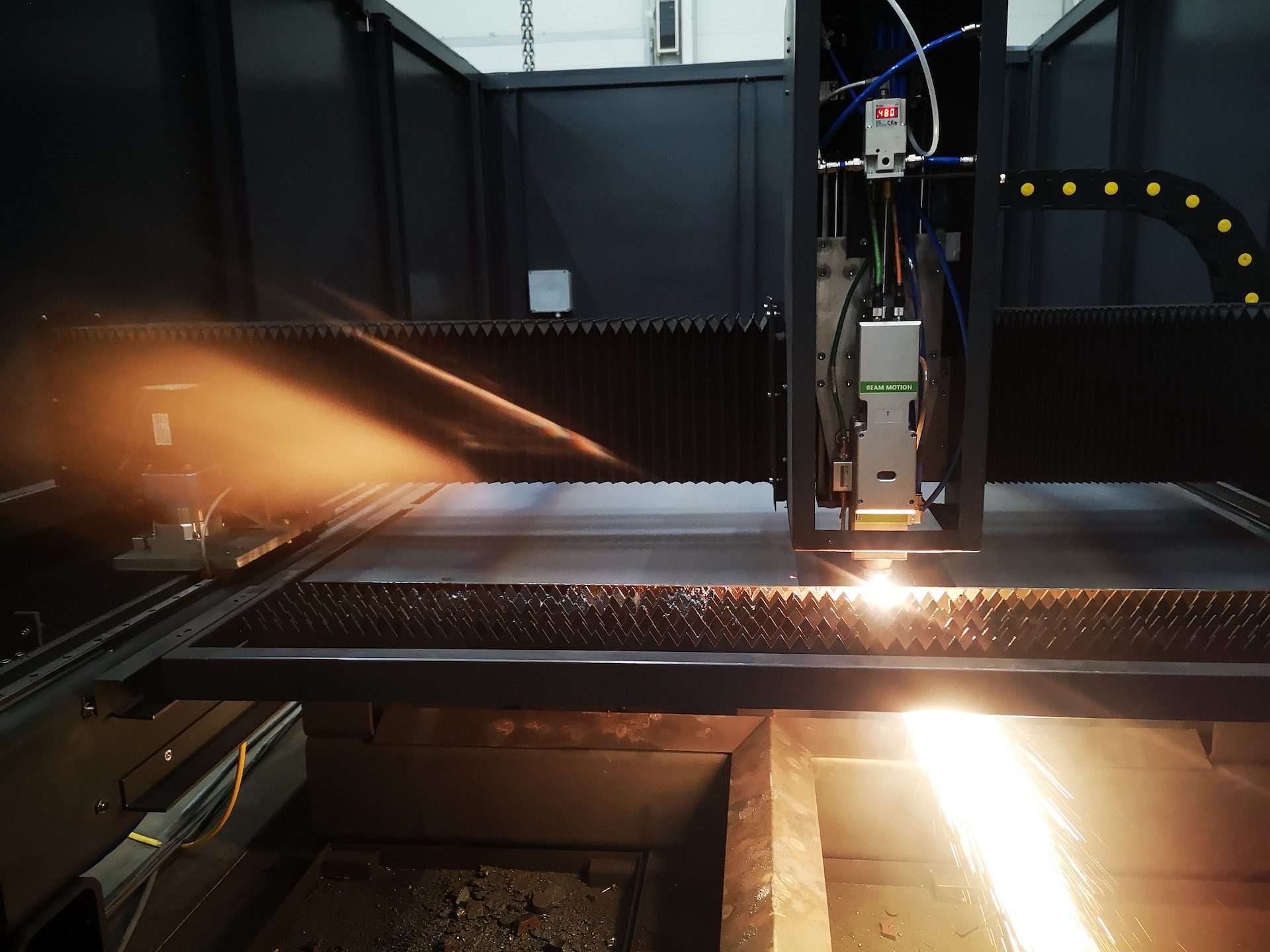

3. Material Preparation:

Galvanization, cutting, and shaping are carried out using state-of-the-art CNC and laser cutting equipment:

◦ Laser cutting machine: Offers high-precision cuts with a tolerance of 0.1 mm.

◦ Edge bending machine: Performs bending operations to ensure maximum strength.

4. Welding and Assembly:

Welding is performed using automated robotic arms, ensuring flawless welds and consistent quality.

5. Surface Treatment:

Both galvanized and powder-coated surfaces are not only corrosion-resistant but also aesthetically pleasing. The average coating thickness is 80–120 µm.

6. Quality Control:

Finished components are subjected to strict testing procedures, including dimensional accuracy (±0.5 mm), surface defect inspection, and load capacity testing.

Product Range

1. Ground-Mounted Systems:

◦ Model X100: Single-row, ground-mounted structure ideal for small residential systems.

◦ Model X200: Dual-row, ground-mounted structure designed for large-scale solar farms.

2. Custom Systems:

For specialized projects, we offer custom-made structures tailored to client needs. Examples include solar systems for the agricultural sector or industrial facilities.

Sustainability and Innovation

Our goal is to ensure that our products are not only efficient but also sustainable. During production, we strive to minimize waste and recycle all excess materials. For instance, last year, we reduced waste generation during production by 15%.

Client-Centric Approach

We believe that our clients’ success is our success. Therefore, we assign a dedicated engineering team to each project, guiding the process from design to installation. We provide a 20-year warranty on our mounting structures.

Closing Thoughts

Total-Gép Kft. is committed to quality, innovation, and sustainability. With our solar panel mounting structures, we contribute to a greener, more sustainable future. If you have any questions or would like to initiate a collaboration, feel free to contact us!

CONTACT

Headquarters/Place of business

Hungary

H-8315 Gyenesdiás

Iparosok útja 7.

Opening hours

Mo-Thu: 07:00-17:00

Friday: Closed

Saturday: Closed

Sunday: Closed

Management

Simon Csaba

Management

simon.csaba@totalgep.hu

Financial Director

Czinger Renáta

Financial Director

penzugy@totalgep.hu

+36 30 477 8959

Technical Director